Glass

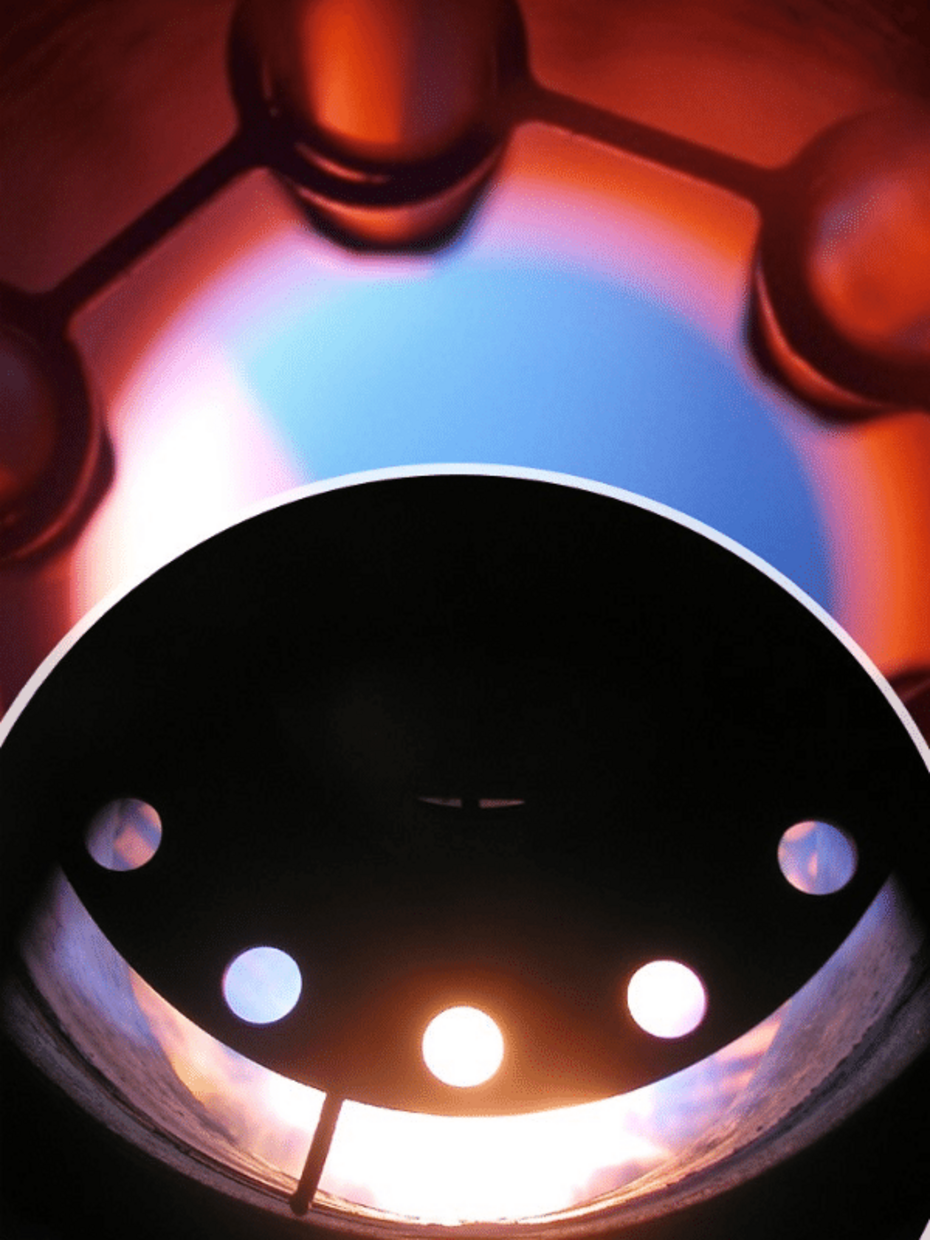

Precision combustion products, systems, and solutions for the glass industry

Today’s glass industry requires highly accurate combustion systems and precision-controlled thermal systems. Efficiency is at a premium, with many manufacturers using preheated air or oxygen for combustion. Fives supplies tailor-made solutions—including combustion, control and ancillary systems—to improve glass producers’ hot and cold end operations. Our combustion technology enhances melting performance and forehearth temperature uniformity, and provides strong environmental performance.

Advanced combustion engineering for today’s glass producers

Fives offers products and solutions for the glass industry to optimize the entire production process.

Hot end melting: We provide a full range of premium float, batch and continuous melting furnaces:

- North American Oxy-Fuel jet burners

- North American low-NOx Flat Flame™ gas burner

- North American preheated air low-NOx burners

Forehearth and working ends: Fives burners are found on forehearth and working ends where temperature uniformity is required:

Cold end tempering and annealing lehrs: When cooling and strengthening glass, we have different burners to support the specifics of your operation. Our solutions include:

- ITAS Dryflame, a plug-and-play packaged burner

- North American Zephyr™, a packaged burner offering precision and efficiency

- North American Fire-All™, an adaptable nozzle-mix, sealed-in burner

End-to-end combustion systems and services

Fives has the expertise to ensure your project is completed to the current codes, on time and on budget. The systems and services we provide in support of our burners include:

- Combustion systems: oxy-fuel burners, multi-fuel burners, advanced forehearth heating systems, ambient and preheated air burners adapted to clients’ unique requirements

- Control systems: advanced combustion control systems designed for reliable combustion performance

- Ancillary components:

- North American 1008 adjustable port gas control valves

- North American 1008C adjustable port oxygen control valves

- North American 1004 adjustable port air control valves

- North American 7218 gas ratio regulators

- North American pre-piped assemblies for forehearths

- Field service and sales support are available worldwide via our local offices and partners

Product Finder

Find the combustion solution that fits your needs

Browse and download our related product literature