Unmatched combustion control knowledge, expertise and reliability

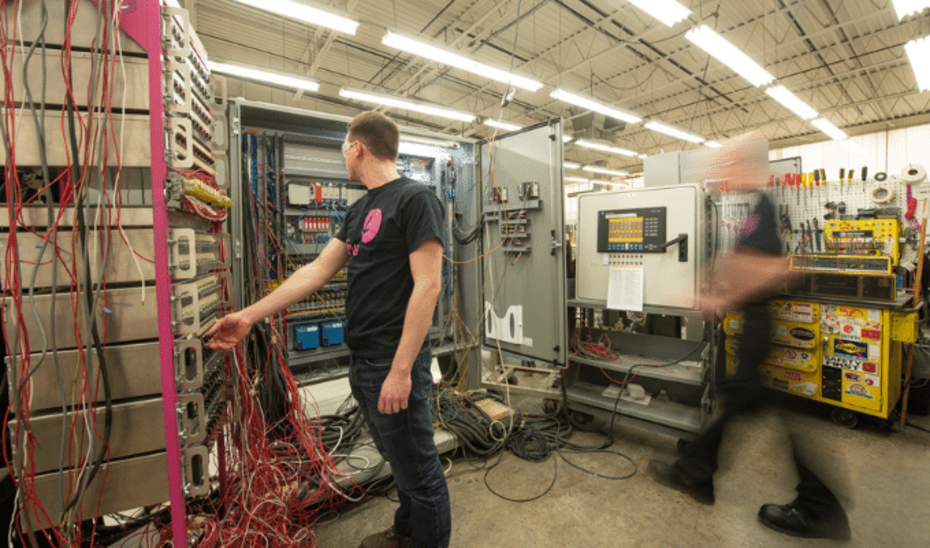

Fives brings high tech combustion controls into your thermal processes, increasing system efficiencies and usability, and streamlining information. Our North American burner management systems (BMS) and combustion management systems (CMS) provide insights and knowledge to help eliminate furnace downtime and improve quality and throughput. Digitizing process information with these systems enables companies to make more informed management decisions.

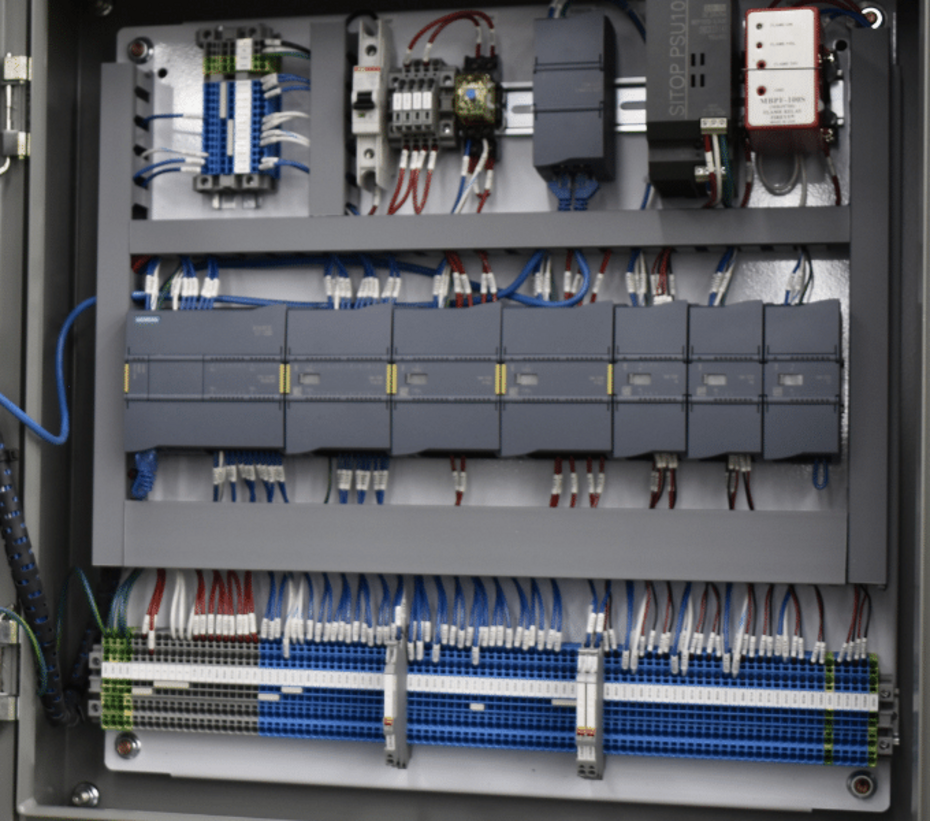

Our North American Safety programmable logic controller (PLC) systems are used in applications worldwide. These include aluminum melting, steel reheating, forging, heat treatment, iron ore pelletizing, tissue paper manufacturing and more.

Unmatched combustion control knowledge, expertise and reliability

Fives brings high tech combustion controls into your thermal processes, increasing system efficiencies and usability, and streamlining information. Our North American burner management systems (BMS) and combustion management systems (CMS) provide insights and knowledge to help eliminate furnace downtime and improve quality and throughput. Digitizing process information with these systems enables companies to make more informed management decisions.

Our North American Safety programmable logic controller (PLC) systems are used in applications worldwide. These include aluminum melting, steel reheating, forging, heat treatment, iron ore pelletizing, tissue paper manufacturing and more.

Global safety and code compliance expertise

Fives has a team of combustion experts in North America with over 100 years of success in engineering and rigorous testing of control systems. The engineering team provides unmatched knowledge of global code compliance standards and the hardware required to suit different process specifications.

Our engineering staff actively participates in National Fire Protection Association (NFPA) committees, which are dedicated to safely meeting the needs of today’s process control challenges. We listen to our customers’ specific needs and process specifications to maximize safety in operational systems.

Thermal process controls knowledge

Our controls systems reflect the thermal process expertise of our engineers, bringing you high quality, reliable process controls. Each team member combines customer process specifications with combustion knowledge to provide a complete system.

A thorough understanding of your processes allows us to design and engineer controls that are the core of your thermal solutions. We are experts in today’s leading controls and automation hardware platforms. We work with customers to build your controls solution around a platform tailored to meet your needs.

Process efficiency and increased throughput

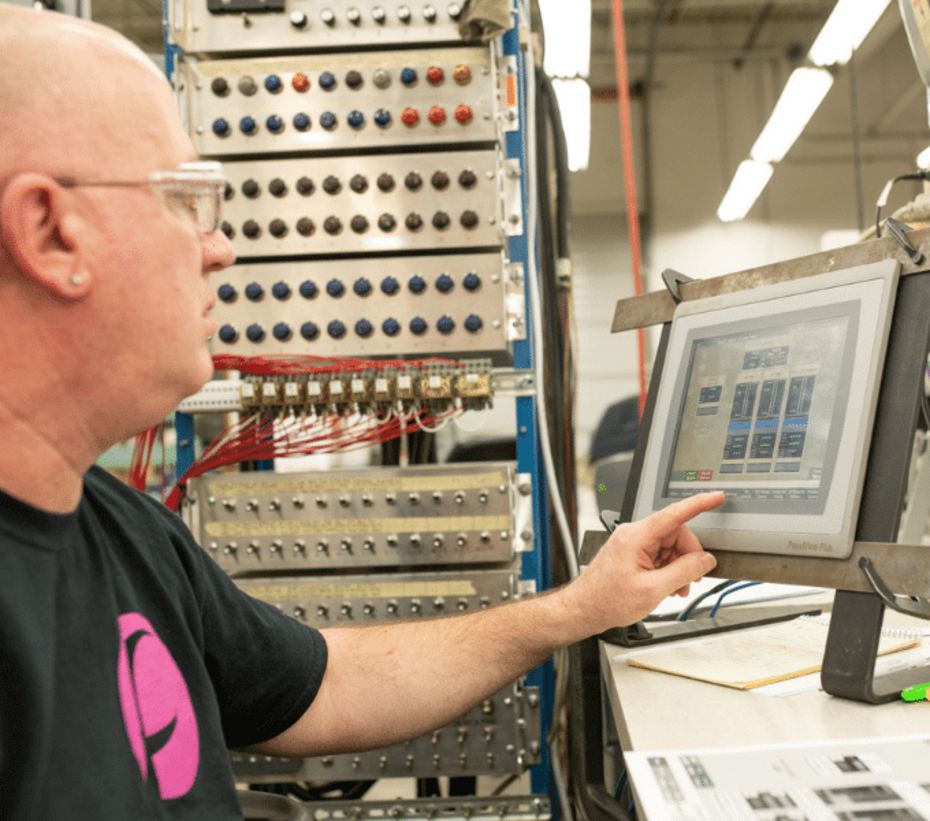

Our cutting-edge controls reduce furnace downtime by providing advanced maintenance warnings. This enables the operator to troubleshoot and resolve potential furnace issues before they happen. The controls provide annunciation and diagnostics that make finding the problem simple and straightforward. Preventing and resolving issues before they happen increases furnace throughput and efficiency.

Our state-of-the-art algorithms minimize fuel use and materials waste, and lower product costs. This increases our clients’ process capabilities and make furnaces more efficient.

Enhance your capabilities with automation

Fives provides fully automated work cells, a growing necessity in manufacturing. Our Level 2 Automation brings material scheduling, tracking, documentation, heat modelling, and handling to your manufacturing processes.

North American Level 2 Automation solutions are ideal for a range of applications, including forging, aluminum melting and heat treatment.

Thermal process visualization and digitization

Our visualization and information systems present relevant data in an easy-to-understand format. This enables our customers to concentrate on running their systems effectively and producing products efficiently. We provide remote diagnostics and monitoring for easy troubleshooting and real-time assistance, anytime and anywhere. Our controls are easily integrated into companies’ industrial internet of things (IIoT) and Industry 4.0 ambitions. They provide insightful process information and increase capabilities for smart reporting.